Projects & Partners

SOL – Sugar Oil as sustainable marine fueLs

This project considers crude sugar oil (CSOTM) as a fuel for internal combustion engines, specifically those that propel sea going vessels. CSOTM is produced from cellulose and a stable blend with fossil marine fuel is created through emulsfication. The SOL project aims to validate the technical and economic viability of this fuel source whilst also achieving a greater than 80% relative greenhouse gas (GHG) emission avoidance during the first ten years of operation compared to the reference scenario.

FACTS & FIGURES

Start date: 01 June, 2023

Duration: 2 years

Amount of innovation fund grant: 4.00 M€

Partner: 1

Fund: Funded by the European Union

HYDROGOLD – Drop-in jet and marine biofuel produced by

hydrogenation of Goldilocks®

Together with our partners Shell and TU/e we developed our breakthrough technology which is known as Goldilocks. This project highlighted the hydroprocessing of our Goldilocks lignin oil to sustainable aviation fuels and other biofuels. Our application was rewarded with 1st place for the innovations of climate-neutral fuels. We are currently still working on our Goldilocks product and advancing it to the next level.

FACTS & FIGURES

Start date: 01 January 2022

Duration: 3 years

Total budget: €499.914

Partners: 3

Co-funded by:

EBI – Engineering Business Intelligence

Engineering Business Intelligence (EBI) will create a new digital method to detect how sub-optimal process operation measured within the process data, affects sustainability, quality and economic value of the process to provide input in mitigation and consequently leverage economics with environmental performance. This novel method will provide detailed insight into the effects of process anomalies, both incidental faults and expected drifts in routine operation (e.g. process fouling), on environmental, economic and consistency performance losses.

FACTS & FIGURES

Project full name: Engineering Business Intelligence

Acronym: EBI

Start date: 01 May 2021

Duration: 4 years, 1 month

Partners: cluster Industry 4.0

EHLCATHOL – Chemical transformation of enzymatic hydrolysis lignin (EHL) with catalytic solvolysis to fuel commodities under mild conditions

The EHLCATHOL research will focus on gaining the knowledge for improving greatly the catalytic activity and stability, mechanism of suppressing recondensation steps, solvation of login, selectivity to fuel molecules, product separation, fuel performance enhancement, combustion of the EHL biofuel, as well as reducing the environmental impact of the emission, all needed to develop the novel EHL catalytic solvolysis technology exploiting the energy, around 40% of the lignocellulose feed, stored in EHL with the highest efficiency. The consortium exists of Aalto, TUE, NTNU, LIKAT, EPFL, CNRS and VERTORO.

FACTS & FIGURES

Project full name: Chemical transformation of enzymatic hydrolysis lignin (EHL) with catalytic solvolysis to fuel commodities under mild conditions

Acronym: EHLCATHOL

Start date: 01 November 2020

Duration: 4 years

Total budget: 4.00 M€

Funding by the EC: 4.00 M€

Partners: 6

IDEALFUEL – Lignin as a feedstock for renewable marine fuels

IDEALFUEL is an EU-funded research and innovation action which aims to develop new production methods for sustainable marine fuels to replace heavy fuel oils (HFOs) in shipping. Due to their fossil origin, the use of heavy fuel oils contributes to global warming and in addition to the emission of greenhouse gases and other pollutants. The goal of the IDEALFUEL project is to create sustainable alternatives by developing new efficient and low-cost methods to produce low-sulphur HFO from wood-based non-food biomass.

FACTS & FIGURES

Project full name: Lignin as a feedstock for renewable marine fuels

Acronym: IDEALFUEL

Start date: 01 May 2020

Duration: 48 months

Total budget: 4.77 M€

Funding by the EC: 4.77 M€

Partners: 11

CHAPLIN – Collaboration in asphalt APplications with Lignin in the Netherlands

The aim of this project CHAPLIN is to evaluate lignin, which is produced in The Netherlands, in asphalt applications and monitor current and novel test roads of selected lignins. CHAPLIN will generate data on the availability of locally and Internationally sourced lignins and study its suitability as binder in hot mixed asphalt. The partners in CHAPLIN cover the full value chain including lignin production, processing of lignin in asphalt, test road construction, and integral knowledge of lignin, bitumen and asphalt.

FACTS & FIGURES

Project full name: Collaboration in asphalt APplications with Lignin in the Netherlands

Acronym: CHAPLIN

Start date: 04 March 2020

Total budget: € 454.382

Funding by the EC: € 454.382

Partners: 16

LOADED – Lignin Oil Based Performance Additives

The objective of the LOADED project is to quantify and optimize these properties, as well as evaluate the compatibility and added value of this bio-based thermoplastic material for use as a performance additive in various commercial polymers, including polyesters, polyolefins and polyamides.

FACTS & FIGURES

Project full name: Lignin Oil Based Performance Additives

Acronym: LOADED

Start date: 01 January 2020

Duration: 2 years

Total budget: € 576.513

Partners: 4

OP Zuid – Doing more with lignin

A switch from fossil-based to renewable raw materials is necessary to reduce the carbon footprint of the Dutch chemical sector. Bioresidues play an important role in this transition as an emerging feedstock for chemicals and materials. The ‘Doing more with lignin’ project sets out to contribute to this goal by setting up a full value chain at pilot scale for lignin-based materials (polyurethane) and chemicals (phenol). Lignin – obtained from biomass – seems to be a very interesting residue as it is a low-cost and abundant renewable raw material.

FACTS & FIGURES

Project full name: European Grant ‘Doing more with lignin’

Start date: 01 October 2019

Total budget: 2.9 M€

Funding by the EC: 2.9 M€

Partners: 3

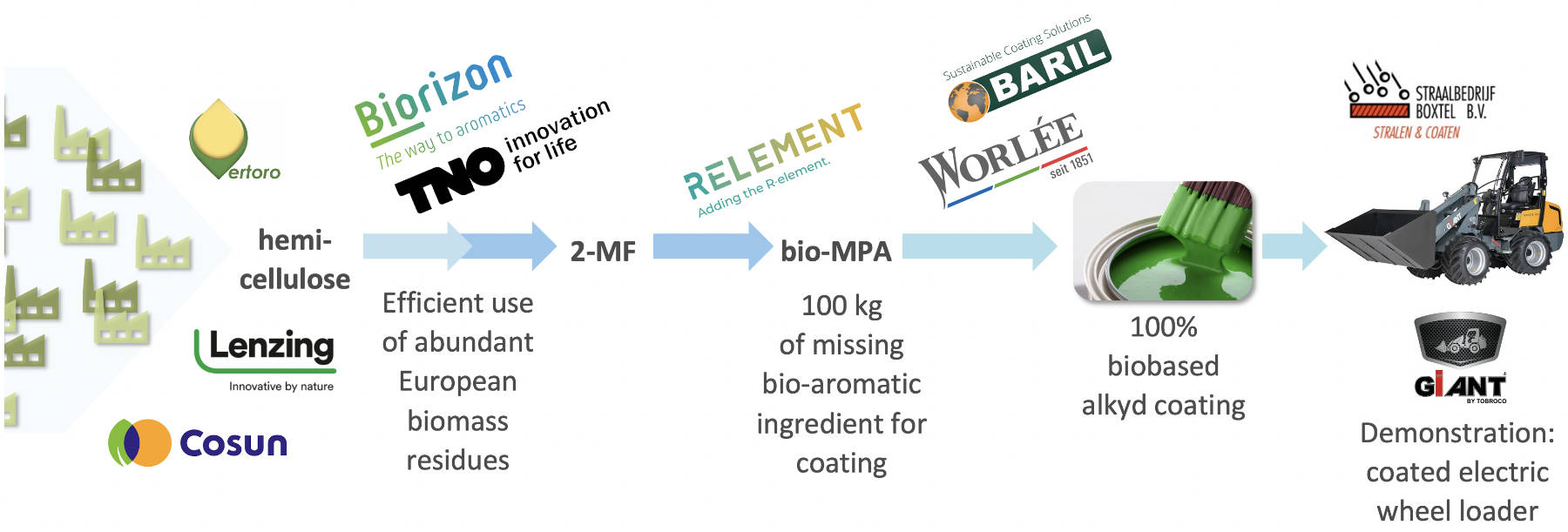

Bright coatings

This project, led by TNO spin-off Relement, will see hemi-cellulose fractions, also one produced by Vertoro, first converted into platform aromatics (2-MF & MPA), and thence processed into a 100% biobased, sustainable coating. This coating will be produced 100kg-scale and ultimately demonstrated on an electric wheel loader vehicle. www.brightcoatings.eu

FACTS & FIGURES

Project full name: Bright coatings

Acronym: –

Start date: 01 May 2021

Duration: 2 years, 5 months

Partners: 3

LIBERATE – Towards a more holistic Biomass pretreatment Technology

LIBERATE aims to realize the first pilot scale plant for the so-called ‘lignin-first’ approach, a novel route produce not only cellulose, but also an aromatic oil directly from woody biomass. These fractions can serve as a feedstock for many fuels and chemicals and will be evaluated by interested third parties. Parallel to these R&D activities, andepth techno-economic and sustainability assessment will be made.

FACTS & FIGURES

Project full name: Towards a more hoLIstic Biomass prEtReAtment TEchnology

Acronym: LIBERATE

Start date: 01 Juni 2018

Duration: 3 years (extended until December 31, 2021)

Total budget: 1.3 M€

Partners: 5

CARBIOW

FACTS & FIGURES

Funding agency: Top Sector Energie (Netherlands)

Start date: October 1st, 2022

End date: March 31st, 2026

Total budget: € 4.850.123

Partners: 14

GOLDILOCKS® BY SEA

FACTS & FIGURES

Funding agency: Kansen voor West – EU REACT program (Netherlands)

Start date: March 1st, 2021

End date: December 31st, 2023

Total budget: € 2.000.000

Partners: 1

LIGNIN2JETFUEL

FACTS & FIGURES

Funding agency: Top Sector Energie (Netherlands)

Start date: March 1st, 2022

End date: March 1st, 2025

Total budget: € 500.000

Partners: 6

HOUDINI

FACTS & FIGURES

Start date: 01 November 2023

End date: 31 October 2025

Total budget: €2.458.176,29

Partners:

Co-funded by:

Cellulose-to-Jet (C2J)

FACTS & FIGURES

Start date: 01 June 2022

End date: 31 March 2025

Total budget: € 2.066.212,40

Partners:

Co-funded by:

SLICE

FACTS & FIGURES

Project full name: ValoriSation of LIgnin to bio-based Chemicals and fuEls

Acronym: SLICE

Start date: 01 Jan 2023

End date: 31 Jul 2026

Total budget: 2.6M€

Funding by the Just Transition Fund (JTF): 2.1 M€

Partners:![]()

![]()

CSO

FACTS & FIGURES

Project full name: CSO – The Future is Sweet

Start date: 23 Jan 2023

End date: 31 Jul 2025

Total budget: 4.0M€

Funding by the Just Transition Fund (JTF): 2.0 M€

Partners: