Our Technology

Robust. Simple. Flexible.

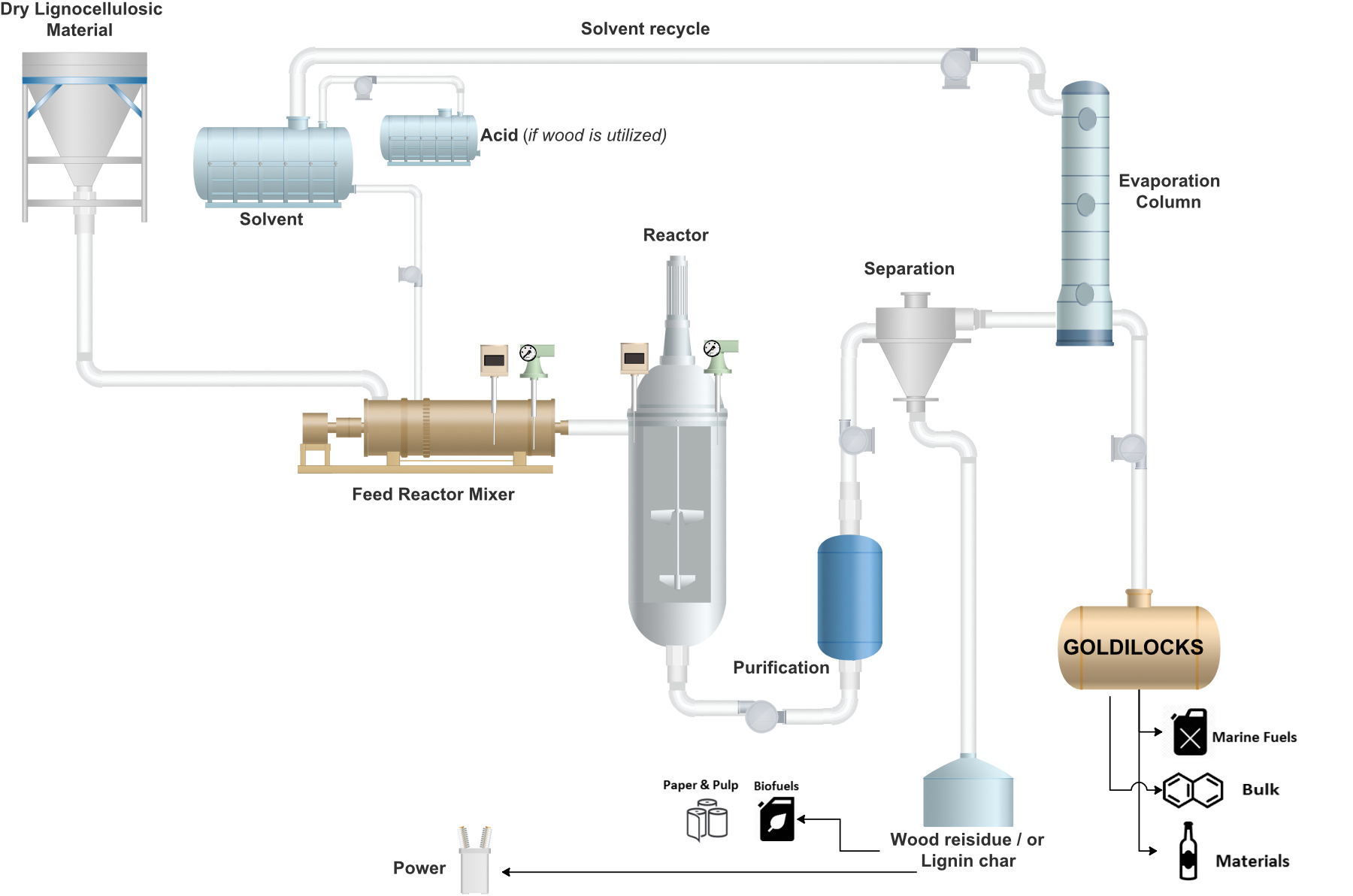

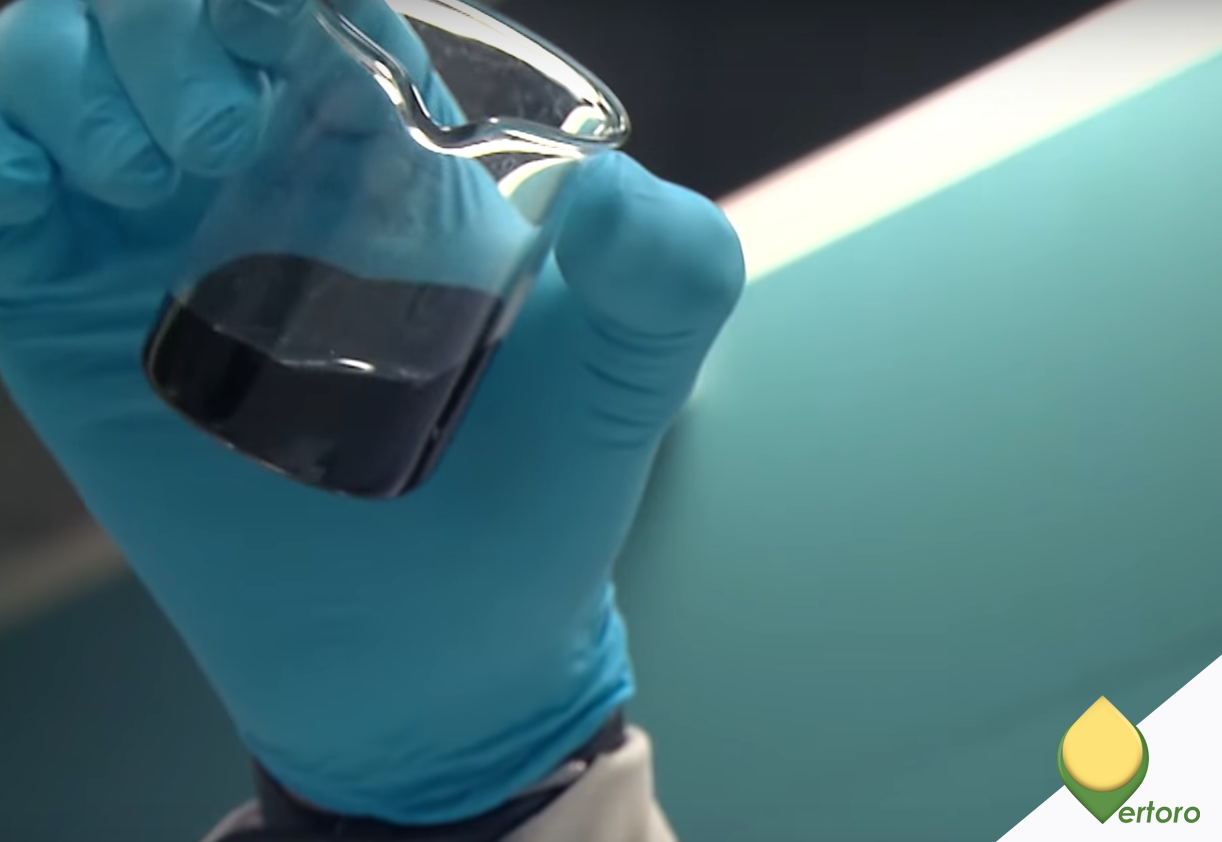

As the world increasingly moves away from petrochemicals, our brand new technology demonstrates how a renewable raw material can be manufactured into wide spectra of future bio-based products. Goldilocks®, our green gold, originates in woody bio-mass or plant-based lignin. We mix it with a solvent, heat it, and out comes our green gold. This platform product can then be used for different applications – to make materials, various chemicals, and fuel (additives). We’re well on our way to producing a platform product with huge market potential, that is able to answer to the urgent need to transform our fossil-based economy to a more sustainable one.

Let’s be the change.

Lignocellulosic biomass is the most economical, abundant and highly renewable natural resource in the world. It has the potential to become one of the world’s primary sustainable resources. Our feedstock policy focuses on the use of residual biomass as a starting material instead of using virgin plant material. The three main components of biomass are cellulose (40-50%), hemicellulose (20-30%), and lignin (10-25%). Cellulose and hemicellulose are currently employed in different industrial applications such as paper making and ethanol production. However, the heterogeneous mixture of lignin fragments is difficult to process when isolated. As a result, it cannot be considered an adequate feedstock for the industry, which requires uniform raw materials with consistent quality. Consequently, less than 2% of the lignin generated annually by these industries is valorized.

Nonetheless, lignin is a versatile molecule with aromatic structure and phenolic functionality. It is a valuable bio-based raw material that can replace a significant fraction of petrochemicals that are harmful to the environment. As such, it can play a buffering role capable of mitigating the negative effects of the future ‘oil crunch’ we might need to face. In addition, lignin has other outstanding attributes: it is biodegradable and a natural UV-blocker, antioxidant, anti-microbial, natural glue-like, hydrophobic, and flame retardant.

Thanks to our unique, patented thermal solvolytic process (WO2019/053287), making Goldilocks® is much like preparing an espresso: we ‘simply’ cook solid lignin in any commercially available polar organic solvent (e.g. methanol, ethanol) for 30 minutes, using moderate temperatures (200ºC) and pressures (<50 bars). No additional catalysts are required.

In fact, we have developed and patented (EP19200489.3) a sister process for also producing Goldilocks® directly from lignocellulosic biomass (i.e. woody residues) to resolve future issues on availability of biorefinery lignin. This process can also be applied on wide range of residual biomass streams.

In addition, due to this mild processing, the lignin Goldilocks® remains in its natural polymeric structure, slightly fragmented in the form of oligomers, which are now meltable and soluble in any polar organic solvent. Since this configuration is maintained, we are able to keep all high-value functionalities of lignin that are lost when broken into monomers, as current approaches do. These features are later transferred to the resulting materials, fuels or chemicals, thereby greatly improving their properties.

Goldilocks® – Limitless possibilities.

By bringing Goldilocks® to market, Vertoro is offering an altogether new kind of green platform product that can be used to make materials, fuels, and chemicals. Countless downstream applications are possible. Goldilocks® allows our customers to significantly decrease their carbon footprint, without rising costs. We look forward to discussing the tailor-made solution that will allow you to sustain your business without having to change your hardware.

In the children’s story, little Goldilocks tries out the porridge, chairs and beds of the bears. They are either too hot or cold, hard or soft. But there is one option, belonging to the little bear, which is just right for her. Similarly, we have managed to create stable lignin oligomers that are just right: because they are solvent soluble and melt-flowable they are easy to process, yet they still retain their natural properties. Hence, Goldilocks®.

Scientific Publications

- Obydenkova et al., Bioresource Technology, 243, 11, 589-599, 2017, Environmental economics of lignin derived transport fuels. [Publication]

- Kouris et al., Topics in Catalysis, 61, 18, 1901-1911, 2018, Scaling-up catalytic depolymerization of lignin: performance criteria for industrial operation. [Publication]

- Obydenkova et al., Bioresource Technology, 291, 12, 121805, 2019, Industrial lignin from 2G biorefineries – Assessment of availability and pricing strategies. [Publication]

- Kouris et al., Patent Application WIPO/PCT, WO2019/053287, A method for obtaining a stable lignin: polar organic solvent composition via mild solvolytic modifications. [Publication]

- Kouris et al., Sustainable Energy & Fuels, 2020, Mild thermolytic solvolysis of technical lignins in polar organic solvents to a crude lignin oil. [Publication]

-

Brown et al., Chemical Engineering Journal, 2020, A novel semi-batch autoclave reactor to overcome thermal dwell time in solvent liquefaction experiments. [Publication]

- Obydenkova et al., Modeling life‐cycle inventory for multi‐product biorefinery: tracking environmental burdens and evaluation of uncertainty caused by allocation procedure. [Publication]

- Kouris et al., Catalysts, 2021, The impact of biomass and acid loading on methanolysis during two-step lignin-first processing of birch wood. [Publication]

- Jedrzejczyk, Kouris, Boot et al., ACS Publications, 2021, Lignin-Based Additives for Improved Thermo-Oxidative Stability of Biolubricants. [Publication]